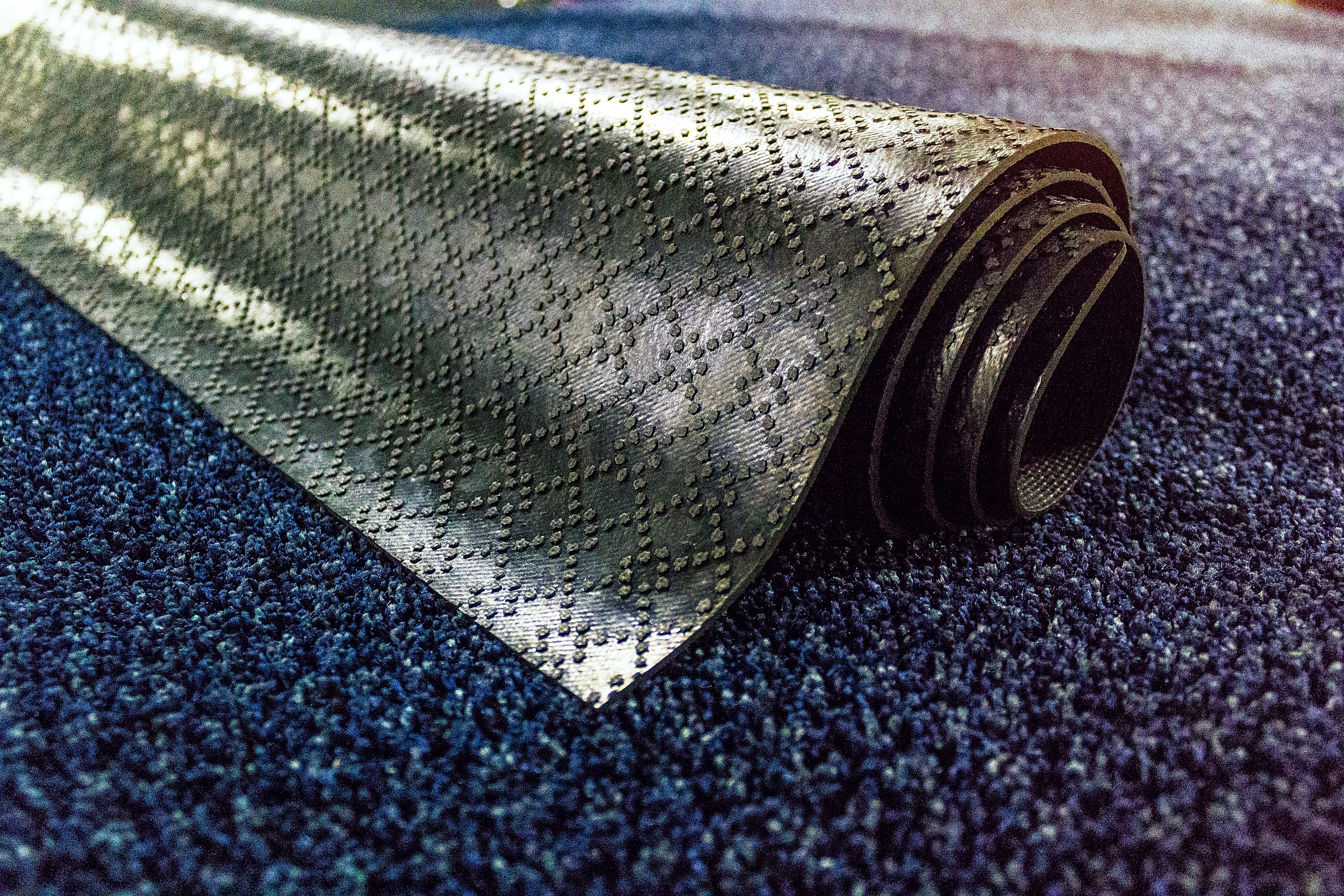

Nitrile Rubber Backing: The Foundation of Superior Commercial Matting

When it comes to commercial floor matting, what lies beneath the surface is just as critical as what meets your vision. The backing material of a floor mat serves as its foundation, determining everything from durability and safety to long-term performance and cost-effectiveness. This is why Health Mats products use the strongest nitrile rubber backing ever manufactured for launderable mats – because quality materials aren’t just a feature, they’re a fundamental requirement for commercial environments.

Why Mat Backing Material Matters

In commercial and industrial settings, floor mats face constant challenges. Heavy foot traffic, wheeled carts, cleaning chemicals, moisture, and temperature fluctuations all conspire to break down inferior materials. A mat is only as good as its weakest component. That weak point? It’s all too often the mat’s backing, which makes choosing the right backing material one of the most important decisions affecting how well your commercial mat performs. After all, when backing fails, mats curl, slip, and tear, becoming safety hazards rather than safety solutions.

Nitrile Rubber to the Rescue!

Traditional rubber lacks the resilience needed for long-term performance. While it provides good durability and grip, it faces a critical vulnerability: rapid deterioration when exposed to substances commonly found in commercial environments (like grease, oil, gasoline, and industrial cleaning chemicals). These substances break down conventional rubber backing, causing it to crack, harden, and lose its grip. This is especially problematic in automotive facilities, building entrances, manufacturing plants, commercial kitchens, and maintenance areas – locations where durable matting is most critical.

Enter nitrile rubber.

Nitrile rubber is specifically engineered to resist chemical degradation. It maintains its structural integrity and performance even when regularly exposed to petroleum products, oils, greases, and harsh cleaning agents, providing a superior backing material that withstands real-world commercial conditions.

Key Benefits of Health Mats’ Premium 90-Mil Nitrile Rubber Backing

When you choose Health Mats, you’re not just purchasing a floor mat; you’re investing in engineering excellence built on the foundation of superior materials. Health Mats takes nitrile rubber backing to the next level with an industry-leading 90-mil thickness applied throughout the entire mat surface. This substantial thickness provides several critical advantages:

- Available in cleated or smooth backing configurations

- Industry-leading 90-mil rubber thickness throughout entire mat

- Built to last through years of commercial use

- Resists oil, grease, and harsh chemical exposure

- Lays flatter, dramatically reducing the formation of problematic wrinkles and ripples

- Curved corner designs for enhanced performance and aesthetics

- Eligible for Health Mats recycling program for responsible end-of-life disposal

Here’s why this all matters to you when investing in commercial floor matting.

Unmatched Durability

The robust construction creates a resilient barrier that withstands years of punishment from foot traffic, equipment, and cleaning processes. Meanwhile, the 90-mil thickness prevents premature wear-through, extending mat life significantly beyond thinner alternatives.

Superior Grip and Safety

Thickness also contributes directly to grip performance. The substantial 90-mil rubber layer maintains constant contact with floor surfaces, creating friction that prevents shifting and sliding. For interior entrances and high-traffic areas especially, this keeps mats securely in place where they’re needed most, which translates directly to better accident prevention.

Resistance to Curling and Deformation

One of the most common mat failures is edge curling, which creates trip hazards and reduces effective coverage. The 90-mil nitrile backing provides the weight and rigidity needed to keep mats flat and functional, even in areas exposed to heavy cart traffic or frequent cleaning.

Enhanced Chemical Performance

The nitrile compound eliminates chemical reactions that plague inferior backing materials. Whether exposed to motor oil in automotive facilities, grease in commercial kitchens, or industrial cleaning solutions in manufacturing plants, this backing maintains its integrity year after year.

Sustainability Through Longevity

Quality materials contribute directly to environmental responsibility. Through partnerships with manufacturers, Health Mats has established a recycling program where nitrile rubber mats can be repurposed once they’ve hit their end-of-life limit. The exceptional longevity of nitrile rubber backing means fewer mat replacements, reducing waste and resource consumption over time. When materials last longer, sustainability inevitably follows.

Our Nitrile-Backed Products

The following commercial mats from Health Mats offer nitrile backing:

Good Performance Requires Material Quality

In commercial matting, cutting corners on backing material leads to premature replacement, costly safety incidents, and ongoing maintenance headaches. Health Mats’ premium 90-mil nitrile rubber backing represents a commitment to performance that pays dividends throughout the mat’s lifecycle – in safety, durability, appearance, and total cost of ownership.

Do yourself and your business a favor and upgrade to Health Mats nitrile-backed mats today.